Issue 167 May - June 2025Please note: The issue content below is just a summary of the articles in the printed magazine.

The articles are not available on-line.

Please refer to the printed magazine for the complete article.

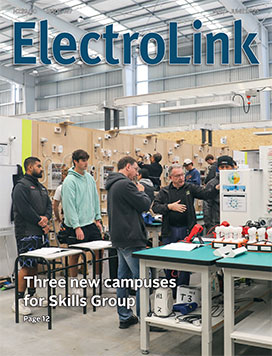

COVER STORY

Three new campuses for Skills Group

Now nearing completion of its three-year plan to convert Skills Group into a private training establishment, Skills has broadened the scope of its campuses with a strong focus on apprentice training and meeting the needs of employers.

Skills new director of specialist trades, Di Lithgow, says this has been challenging over the past few years with major changes to vocational training, but Skills has stayed on course to become a New Zealand leader in training delivery and recognised as a high-quality training provider.

This commitment to quality training can be seen in the investment Skills Group has made in its new campuses in Dunedin, Christchurch and Auckland. Trebled in size and outfitted as state-of-the art training facilities, these new campuses set the benchmark for Skills’ Specialist Trades School training.

Skills Group Specialists Trades Training operates in 14 campuses throughout the country and has gone through a series of planned changes following the completion of its acquisition of the Electrical Training Company (Etco) in April 2023. This purchase of Etco and its group apprentice operation was of such a scale that it enabled Skills to develop a new operating model across all its business units and brands.

Lithgow says this new model has aligned the activities of Skills and Etco and allowed their shared services teams to streamline their operations and create customer-centric and more efficient training processes.

Today the Skills Group provides training services from 17 sites for 20,800 learners across 33 industries. To deliver this, Skills separated its vocational training and higher education (including Ignite and Premier) from its training designed for specialist trades.

Skill’s Specialist Trades Training now includes Etco’s group employment scheme, and streamlined systems and processes are in place for training in electrical, electronics, telecommunications, gasfitting, plumbing, drainlaying and roofing. Electrical training is delivered in ten of the campuses while plumbing is delivered in four of them. Etec industry courses are delivered online out of Auckland and its block courses are held in the campuses.

Please refer to the printed magazine for the complete article

NEWS

Electrical training reform gets underway

In the biggest upheaval to vocational training since the last big upheaval, the government announced in April its decision to introduce a new industry-led, independent, work-based learning model for apprenticeships.

This reforms the changes made to trade training under the Reform of Vocational Education (RoVE) in 2020 and restores the scope for industry sectors and employers to drive apprenticeships the way they want under a model similar to the way former industry training organisations (ITOs) used to work.

The government intends to implement this more traditional model by creating new Industry Skills Boards and tasking them with setting standards for qualifications that will be available to all training providers to deliver.

These Industry Skills Boards (ISBs) will be established on 1 January 2026. They will be recognised in empowering legislation as part of the Crown, but with majority industry governance. They will be responsible for developing qualifications, endorsing training programmes and moderating assessments in key industry sectors. ISBs will also be required to provide workforce analysis for their sectors and advise the Tertiary Education Commission (TEC) on investment required for training.

These new skills boards will replace the Workforce Development Councils (WDCs) that were set up by the previous government to replace industry training organisations (ITOs) in 2020. These industry-owned organisations used to set training standards and managed most work-based learning. The government scrapped ITOs five years ago when it repealed Industry Training and Apprenticeships Act and transferred the standards-setting functions of ITOs to WDCs and moved their work-based learning functions to work-based learning divisions of Te Pukenga or to private training establishments (PTEs).

From 1 January 2026, the newly-established ISBs will take over the standards-setting role from the WDCs and will be required to ensure the vocational education and training in the work areas they are responsible for is relevant, credible and consistent throughout the country. The current WDC functions include developing qualifications and standards that training providers use to design programmes and providing quality assurance in their use.

Work-based learning for these qualifications will be offered by existing and new industry-owned PTEs, institutes of technology and polytechnics (ITPs) and by wananga. These training providers will manage all aspects of an apprenticeship or traineeship, including the pastoral care for learners.

Please refer to the printed magazine for the complete article

NEWS

Who is going to drive electrical training?

The government’s decision to disestablish Te Pukenga and restore local and industry decision-making for training in the electrical industry is now going to depend on two key decisions that have yet to be made: will the electrical industry be given its own industry skills board (ISB) to drive the development of its training and apprenticeships; and how will that ISB be set up and governed to ensure the right training is developed and delivered.

So far, the government appears to have decided that the transition from Te Pukenga to the new vocational structure would be more efficient if the new ISBs managed the transition rather than the Crown. According to the Minister for Vocational Education, Penny Simmonds, this will “provide more space for innovation and improvements in work-based learning to emerge” and also give “industries, rather than the Crown, responsibility and control over who offers their work-based learning.”

This solution is designed to cause less disruption and give private training providers more scope to manage all aspects of apprenticeships and traineeships including pastoral care from the outset.

But the problem the electrical industry now faces is just how much control it will have to achieve these objectives if training in electro-technologies is placed under the control of the construction industry as the government has proposed.

The current proposal breaks the wider electrical industry up. The electricity supply sector is being placed under an ‘infrastructure’ ISB and electro-technology goes under a ‘construction’ industry ISB as one of its subsectors. There also appears to be a third overlap under an ISB for ‘manufacturing’.

This means electro-technology training will still be industry-led as the government intends, but led by industries other than the electrical industry.

Please refer to the printed magazine for the complete article

NEWS

Industry association investigated for cartel conduct

An electrical industry trade association has narrowly avoided prosecution for alleged anti-competitive conduct. In a publicly available letter dated 15 May 2025, the Commerce Commission told the NZ Trade Group Limited (NZTG) that it had investigated the allegations and would be taking no further action beyond providing compliance advice to NZTG and a number of its members on how to “avoid contravening the Commerce Act in the future”.

The Commission’s head of cartels, Grant Chamberlain, told the trade group that NZTG’s cooperation with the Commission’s investigation and commitment to promoting understanding of competition law to its members was a factor in its decision not to prosecute. NZTG has undertaken remedial action to reduce the likelihood of any breach of the Commerce Act going forward.

The Commission does not always have to initiate a criminal prosecution even where there is sufficient evidence to provide a reasonable prospect of a conviction. The Commission must also be satisfied that a prosecution is in the public interest. Chamberlain gave no indication of how the Commission arrived at its decision not to prosecute in this case, other than NZTG’s cooperation and “broader priorities”.

Please refer to the printed magazine for the complete article

Installation earthing – why it still matters

Earth electrodes might no longer offer the same level of protection as when the MEN system was developed, but they still have an important safety enhancement role in electrical installations today. Electrical inspector and competency trainer, Warren Harris, explains.

It has been asserted over recent articles that the purpose of an earth electrode on an installation is solely for the benefit of the electricity distributor. Distributors have their own earthing systems within their network to maintain a connection between the neutral system and the mass of earth, and they are tested regularly. Earth electrodes do provide a safety benefit to an electrical installation – but the benefits aren’t what they used to be.

Our MEN system, the electricity system of supply that has governed how we earth an installation back to the supply system, has been in place for many years. When it was first implemented, each house was connected to each other house using the water reticulation system, which at the time was metallic. However, as time progressed the arrival of plastic products became commonplace and they started to replace water mains with plastic piping, giving our MEN system a large dent in its safety. This is why it is no longer permitted to use water (or gas) mains as your main earth electrode.

Please refer to the printed magazine for the complete article

COVER STORY

How AI can aid industrial automation

Talk of artificial intelligence (AI) seems to be everywhere at the moment! Claims and counter claims have been made, some quite fanciful, others somewhat extreme. So what’s really happening? Is AI really permeating every aspect of our lives or threatening to do so or are the scaremongers overreacting?

AI is a very broad topic so we will restrict ourselves to how it can be applied to industry. But AI still poses many questions for industry, like is it realistic to think that entire machines or plants will one day be created and run by AI systems, without any human intervention? How far has AI already seeped into industry and what will the future hold? What are the employment ramifications for those of us currently in industry? AI has also introduced a whole new vocabulary, so we’ll try to explain the new terms as we progress.

What is AI?

Computers have for many years had some degree of autonomy. They can, for example, self-diagnose internal faults and raise alarms accordingly. Also, being programmable means they’re able to make decisions for themselves, although they can still only do this within the confines of how they have been programmed.

AI tries to take all this a step further by making computers so ‘intelligent’ that they simulate human thought processes. It does this by applying its own ‘reasoning’ to decision making, when solving problems. While AI may appear to ‘think’ for itself (much like a human) it’s still generated by a computer.

Please refer to the printed magazine for the complete article

COVER STORY

Bathroom lighting approaches

Bathrooms, they may be one of the smallest rooms in any building, but a bathroom is one room that is to be found in nearly every lighting project, whether it be a domestic residence, an office block, a factory or industrial premise. The bathroom’s role can range from an afterthought, tacked on to a warehouse in a small space down the back, through to the opulence of an ensuite or guest bathroom in an upscale hotel room. No matter where they range on the scale, they all have an element of utility, they are there to perform a specific function, one that effective lighting can greatly assist.

General bathroom concepts

Before looking at specific applications, there is a considerable overlap in general principles of bathroom lighting that can be addressed. Guidelines run from the purely aesthetic, through to common sense and functional aspects but there are also several legal requirements.

The one set of rules that affect all lighting installations within bathrooms is that around ingress protection ratings. IP ratings are not always commonly understood by those outside the electrical industry, especially the very specific rules around which IP ratings must be used in which zones, and how those are categorised. For this reason, luminaire selection, although commonly chosen by homeowners, interior designers or architects, must be carefully policed by the electrical contractor installing them.

Contractors must ensure all luminaires conform with their IP rating and placement within the different bathroom zones. There is also some logic behind these requirements other than just the legal side, with bathrooms being a location subject to often wet, steamy conditions, with high moisture and condensation best suited to higher IP rated luminaires.

Bathrooms also have requirements around ventilation, and one solution to both these legal requirements of IP ratings and moisture extraction can be to utilise purpose made light and fan kits. They provide a simple but effective solution, often have easy to understand guidelines around their room sizing and will provide adequate illumination.

Please refer to the printed magazine for the complete article

Simple solutions for when the office is a headache

Ever since the increase in recognition of mental health issues in the workplace, the importance of the work environment on individual wellbeing has risen in the consciousness of employers. The power of the individual to raise concerns about insufficient or poor-quality lighting in their workplace, backed up by the power of organisations like WorkSafe enforcing health and not just safety requirements means that companies are required to address any concerns.

One such example is when office workers complain of headaches caused by their office lighting. Poor lighting causing negative impacts on health is a well-studied issue and can be a legitimate concern, especially for individuals with other risk factors to photosensitivity, such as autism or those taking certain prescription drugs.

Migraines can be caused by three main contributing factors from light sources. Under or over-lit workspaces, glare and flicker. Under-lit circumstances can also be a symptom of poor luminaire positioning causing shadowing.

Please refer to the printed magazine for the complete article

|