Issue 156 July - August 2023Please note: The issue content below is just a summary of the articles in the printed magazine.

The articles are not available on-line.

Please refer to the printed magazine for the complete article.

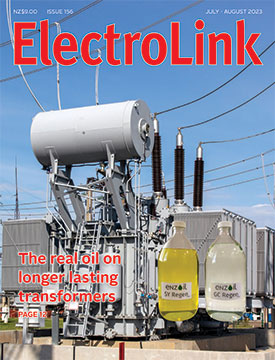

COVER STORY

The real oil on longer lasting transformers

For many years the service life of power transformers has been typically set at 50 to 70 years. Some die a catastrophic death while others are phased out before this can happen. But if an autopsy was performed on these failing assets, the electricity industry would discover that they are dying not from old age, but by being progressively damaged.

The good news, says Brett Hodgson, is that the terminal harm being caused to the transformer windings and other internal components can be arrested immediately with an oil transfusion. If the oil is kept clean using the latest techniques, it could double the service life of a transformer.

As a director of eNZoil, Hodgson, says their processes to regenerate transformer oil remove harmful contaminants and provide greater asset longevity, while reducing the cost of asset maintenance and replacement.

He says oil is the lifeblood of a transformer and eNZoil supplies all the means necessary for transformer owners to get far more performance from their assets than they ever thought possible.

Proof of this is in the quality of the regenerated oil supplied by eNZoil and the higher standard the company applies to its regeneration processes in restoring transformer oil to as good as or better than new oil. This cleansing process is completed by the pre-flushing of existing transformers to remove the last of the harmful contaminants like corrosive sulphur before the regenerated oil is added.

Please refer to the printed magazine for the complete article

NEWS

Wiring complex properties

Just as high-rise apartment buildings created a few compliance challenges for electrical designers a few years ago, the increasing prevalence of high-density housing is raising similar questions as to how to design the distribution of power to multiple dwellings or lockups on the same site.

Electrical inspector, Peter Rigarlsford, says he has come across different scenarios of incoming power supplies to the units and there is no common understanding in the industry on the best way to do it that is both safe and compliant.

Rigarlsford says sometimes engineers want the units to have MEN switchboards with a driven earth electrode or have submains to the units complete with an earth conductor.

“Years ago, we had the scenario of a group of two or three townhouses where each had a supply from overhead or a pillar, and each townhouse had a MEN switchboard complete with a driven earth. The point of supply was clear and that was where the incoming mains crossed the boundary.”

But today with more complex developments, he says locating the point of supply (POS) at the boundary of the property as the POS definition in the Regulations indicates, might not be the best way to do it.

Please refer to the printed magazine for the complete article

Bulletproof polarity testing and how it is regulated

Before certified and inspected prescribed electrical work can be connected to a supply of electricity, the Electricity (Safety) Regulations require verification steps to be carried out to ensure the connection of the work will result in an installation that is safe to use. Regulation 73A prescribes these mandatory steps as follows.

Whether it is adding to an existing installation or installing a new one, no prescribed electrical work can be completed without first applying Regulation 73A. This regulation covers taking a dead physical electrical circuit or in many cases a combination of circuits through the process of ‘connecting’ and ‘enlivening’ to become a useful electrical arrangement which will be ‘safe to use’.

Getting this right will help keep every electrician out of a disciplinary hearing but, when one reads this particular Electricity Safety Regulation, it is found to be deficient in some aspects. It would be one of the few regulations on which a great deal of electrical safety rests, yet there is a ‘disconnect’ gap from the ‘dead circuit’ tests to checking and using the ‘enlivened’ state.

As we look closer at this regulation, there are some details that need analysing:

73A (1) (e) (i) requires the person connecting the work to a supply to ensure that the polarity and phase rotation of the supply is correct.

Please refer to the printed magazine for the complete article

Research underway into solar installation work

Electrical inspector Tony Doyle is undertaking further research on issues faced by the electrical industry. He comments as follows.

I am about to embark on a new personal journey with Capable NZ and Te Pūkenga to undertake research for the Doctor of Professional Practice (DProfPrac), focusing on electrical contracting and renewable energy contracting practices.

The upcoming research will aim to generate substantial original knowledge from and about practices. It is a significant challenge in itself, but to add to the excitement, I am also project managing the overseas construction of a 90 MW solar farm and starting the pre-mobilization considerations for similar farms that are set to be built in New Zealand from the end of this year.

At this stage, as I embark on my research for the DProfPrac, one thing remains clear: the real concerns raised by electrical inspectors in my previous research and commented on in ElectroLink are still fresh in my mind. It seems apparent that the Government lacks a genuine interest in technical electrical matters. If they did, they would have made a more concerted effort to provide industry with the necessary mechanisms for legal compliance when implementing modern requirements and newer technologies.

Please refer to the printed magazine for the complete article

Does manufacturing engineering have a future?

If engineering-based product manufacture is to have an effective future in New Zealand, the country needs a more co-ordinated approach. Lighting manufacturer, John Heimgartner, comments.

Up until the 1980’s our governments incentivised local manufacturing as a means of import substitution. They did this by altering import duties, import licence availability and costs on each product category.

But big changes came in the 1980’s when import licensing was abolished and duties phased out. The effects were gradual but very dramatic. Four brands of a product became 14 brands and more, all fighting for a small market.

Successful manufacturers were those who were quickest to reinvent their product designs and processes to potentially become world leaders in their category while competing with low-cost producers in Japan, Italy, Spain etc but unfortunately ‘imported’ soon sounded like an advantage to the consumer, and ‘proudly NZ Made’ often offering limited choice.

Next up, New Zealand manufacturers contended with low-cost Taiwanese manufacturing. Local innovation allowed many manufacturers to continue and the next storm to weather was Chinese manufacturing dominance in the early 2000’s. Chinese factories blossomed rapidly as a result of still lower manufacturing costs, in many cases government supported, and also their increasing internet visibility.

Please refer to the printed magazine for the complete article

COVER STORY

Implementing a control system

For the last ten years or so, debate has raged throughout the automation industry about the best method of implementing a control system. The merits of using Industrial PCs (IPCs) over traditional Programmable logic controllers (PLCs) have been argued at length. Both sides present some strong arguments in their favour, so it’s unlikely this debate will be settled decisively any time soon.

PLCs have dominated the automation space since they appeared in the 1970s. They’re built on dedicated hardware that’s been especially designed for industry and are often programmed in the traditional ladder diagram or structured text languages. Few could argue that they have established themselves as very robust and highly effective controllers.

IPCs, on the other hand, are relative newcomers to industry but have nonetheless firmly established themselves. They have gained a significant share of the automation market, particularly in the past decade, largely because alongside their control engine they also provide a standard operating system such as MS Windows. This opens up the controller to a host of software possibilities.

It’s important to understand the contention is not so much between vendors, as all the major PLC players include IPCs in their product portfolios and offer comparable functions. The debate centres more around what is the best control methodology for automating machines and production sites.

We present here a case study of where an IPC was used in an upgrade of a large warehousing facility. The decision to use an IPC was based on some distinct advantages it could offer, that would have been very difficult to implement in a traditional PLC.

Please refer to the printed magazine for the complete article

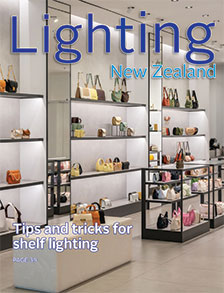

COVER STORY

Tips and tricks for shelf lighting

In this article, we will look at some ways to address how to light up shelving to the maximum effect. Although it seems like a simple task, there are a lot of different variables involved. Shelving ranges from a large installation, like a full wall bookshelf, or a retail shop layout, through to small intimate displays within a home or within a museum to house a small artifact. There are many unique factors with shelving layouts, but there are a common set of themes that require consideration.

Although lighting of shelves, and the objects they hold are very much in the realms of task lighting, they can also be used to create an atmosphere for an entire space. Within a domestic arrangement, shelf lighting can be used as a background lighting scheme. For example, a lounge utilising only shelf lighting as indirect illuminance, can create a pleasant cosy space to comfortably watch television.

Conversely, shelf lighting in a retail shop can play such a predominant role, even over that of the main illuminance sources, that the selection of good or poor shelf lighting can make the difference between a successful and failed venture.

When looking at shelving, the first aspect is to consider the shelves themselves. Good starting questions are what material they are made of, then other physical characteristics like depth, layout and mounting opportunities and constraints for luminaires.

Please refer to the printed magazine for the complete article

The emergence of Li-Fi technology

n July the Institute of Electronic and Electronics Engineers (IEEE), released the 802.11bb-2023 standard for Li-Fi, providing a global framework for the deployment of the wireless technology. This is important news for the lighting industry, as it will speed the uptake for lighting that is enabled with Li-Fi embedded technology. A potential global rollout of mobile phones with inbuilt Li-Fi receivers could be the impetus for a demand of the provision of Li-Fi enabled lighting in our offices, homes and public spaces.

What is Li-Fi

Li-Fi is a type of visible light communication using light to transmit data. Simply put, data is a binary stream of ones and zeros, and Li-Fi at its core is the translation of a light switching on and off at a high rate into a stream of code.

History of Li-Fi

In 1880 Alexander Graham Bell invented a device called a photophone and believed that this was his greatest achievement. The photophone was a device to relay speech over long distances using modulated sunlight. This technology later became the backbone for fibre optic technology and a precursor to the new Li-Fi technology. In 2011, Professor Harald Hass introduced his newly termed Li-Fi system, where he demonstrated a high-definition movie playing through data transmitted by a standard LED lamp.

Please refer to the printed magazine for the complete article

|