Issue 159 January - February 2024Please note: The issue content below is just a summary of the articles in the printed magazine.

The articles are not available on-line.

Please refer to the printed magazine for the complete article.

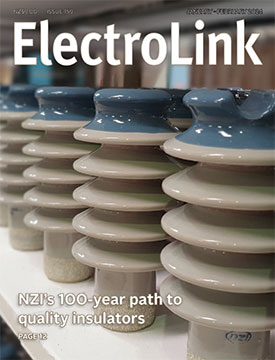

COVER STORY

NZI’s 100-year path to quality insulators

Distributing power to wherever it is needed throughout the country depends on the long-lasting quality of conductors, but it depends even more on the long-lasting quality of the insulators that support them.

Insulators are the unsung heroes of the national grid and local networks, and no company has been supporting power networks longer than New Zealand Insulators.

This Temuka-based company has been turning clay and sand into porcelain insulators for 100 years now and is looking forward to the next 100 years because there is no more durable insulating protection for power lines than expertly made porcelain insulators.

New Zealand Insulators’ general manager, Chris van der Werff, says NZI has built its expertise in porcelain manufacture on the unique strength of the Kakahu clay from the company’s opencast mines and the seven ingredients it blends to produce each finished insulator.

Van der Werff says NZI, as a cornerstone ESI brand, will never change its focus on making the best insulators on the market because anything less than the best is a false economy for network owners.

He says research shows that in a network build, the costs associated with insulators for a new line is typically only three to five percent of the total build cost.

“But when you examine where faults occur throughout the life of the line, 95 percent of the failures on a network are associated with insulators.”

Please refer to the printed magazine for the complete article

NEWS

New scope for AS/NZS 3000

Now that Standards Australia has set up a new leadership team to direct the future development of all the electrical standards run by its EL-001 committee, we are seeing a new direction starting to form in alignment with the changes needed to improve the resilience of supply while accommodating distributed generation and portability of electricity supplies coming from electric vehicle charging.

Representing Standards NZ on the new EL-001 executive committee, electrical inspector Peter Morfee has put forward a 16-point plan of the strategic changes needed to bring electrical standards into a new set of Wiring Rules to advance technical safety.

Morfee says a lot of the issues that need to be addressed will take a few years to sort out, but work has to get underway now and in the right sequence so that solutions to the technical challenges can be put in place before fires and electrocutions start to occur.

On the path to achieving this, he says decisions have to be made on how the companion standards to AS/NZS 3000 are going to be treated and that will likely include a reconsideration of the international Wiring Rules, IEC 60364. Part of that review will include decisions on how deep prescriptiveness should go to minimize complexity, and how to make the best use of digital options to reduce the requirement for calculation tables and increase the accessibility of the content when electrical workers are looking to develop a compliant installation.

Please refer to the printed magazine for the complete article

NEWS

EWRB revokes connection

n eight months’ time, widespread changes to the electrical work the EWRB authorises licence holders to carry out will begin to come into effect. These changes include revised requirements for registration across all classes and the introduction of new endorsed classes of registration and licence to recognise the unique risks in particular working environments.

The EWRB calls its new licensing structure a Stepped Framework and currently licensed workers will soon find themselves out of step with the new regime in certain areas until they gain the appropriate licence endorsements to allow them to carry on with any work they have been doing in medical cardiac protected areas, hazardous areas, mains parallel generation systems and also supervision.

In October 2023, the EWRB provided on its website a brief explanation of its new Stepped Framework for licensing and said that it had also changed “the limits of work that can be carried out by each class of registration to align more closely with the Electricity (Safety) Regulations 2010”.

Unfortunately for every licensed engineer, electrician and inspector carrying out prescribed electrical work for an installation or a works, these limit changes are as significant as they are contradictory to the regulations the Board is claiming they align more closely with.

Please refer to the printed magazine for the complete article

Preventing future fatalities

Electrical inspector Tony Doyle comments on outdated wiring rules and their effect on electrical safety

As we step into 2024, emerging details shed light on a tragic incident from 2020. A prosecution related to this incident is nearing conclusion, involving an individual who suffered a fatal electric shock. It is understood that the electrician involved was found guilty of carrying out the prescribed electrical work (PEW) of installing a range-hood appliance, leading to another tradesperson receiving a fatal electric shock while touching the metalwork of the appliance.

An electrician was prosecuted under section 163C of the Electricity Act 1992 (offences for actions or omissions likely to cause serious harm or significant property damage). Sentencing will happen early in 2024 and the offence carries a maximum prison sentence of two years and/or a fine of $100,000. The industry will be keen to learn what we can from this most unfortunate circumstance.

Please refer to the printed magazine for the complete article

2020 Nelson rangehood fatality

Following a fatality in 2020 a Nelson electrician was found guilty in November to a charge laid under the Electricity Act. On behalf of NZEIA, Wellington-based electrical inspector and professional electrical engineer, Mark Harris, has produced the following description of what occurred from multiple sources. He also provides commentary and advice on how to prevent the same unsafe situation from occurring again.

n 2020 a person died after touching the metalwork of a rangehood appliance while upgrading a kitchen, after an electrical worker had undertaken electrical work.

This tragedy deeply affected all involved and was 100% avoidable.

An electrician was engaged to remove an existing hardwired fan-and-light unit (refer Figure 1) and install a new socket outlet in its place (refer Figure 2) for a new rangehood appliance.

The electrician cut the cable off the old fan-&-light unit, complete with the non-visible sleeved earth conductor inside, before fitting the new socket outlet in its place. The double-gang switch plate was not removed as part of the work, nor for testing. The new rangehood was then mounted and plugged in.

A CoC with test results was issued for this work.

After being in use for approximately two weeks, a non-electrical contractor was engaged to carry out further work in the vicinity of the new rangehood. He received a fatal electric shock, with an entry wound consistent with contacting the live metalwork of the rangehood.

Please refer to the printed magazine for the complete article

Practical safety testing of electrical installations

To encourage more safety testing to be carried out, electrical inspector and EWRB competency course provider, Al McGregor, recommends the testing methods cited in AS/NZS 3017 be reviewed. He has been teaching apprentices since 1972 and his background includes an NZCE and working as electrical engineer at Wellington and Rotorua Hospitals and consultant work.

This article is a critique on the test methods utilised in the testing standard AS/NZS 3017. This standard is called up by AS/NZS 3000 as a means of complying with testing requirements.

Even though 3017 has been recently revised, its methods are largely unknown and rarely practised. Too often they are difficult, invasive, time consuming and outside the limits of permitted work.

A fresh revision of this standard could make it a useful document.

This article considers just the earthing tests required of common electrical work. It offers alternative procedures which have been proven in the field over many years and give equal or better results than 3017’s.

Please refer to the printed magazine for the complete article

Coming changes to licensing

The creation of new licence classes by the EWRB and the limits of work imposed by the Board along with other Board interpretations of electrical law have raised concerns in the industry. Electrical inspector, Alec Knewstubb, comments on these issues.

He is currently the president of Electrical Safety NZ Inc and has represented Master Electricians for 15 years on several standards committees including EL-001 for AS/NZS 3000 and its companion standards. However, the views expressed here are the writer’s own, and do not necessarily represent the view of any organisation.

The latest issue of ElectroLink included an article about the coming changes to licensing for most electrical workers (“New registration classes causing confusion”; Nov-Dec 2023, page 8). This article follows on from that but isn’t about the details because, while over coming months we are all going to have to come to grips with the specific details that will affect us personally, there are bigger, more important issues at stake.

Please refer to the printed magazine for the complete article

COVER STORY

User associations and online resources advance technology

In the last decade, the industrial sector has faced a multitude of demands. To accommodate the growing number of customer requirements, the imperative of adopting heightened automation technologies and optimised production processes, has become increasingly apparent.

The surge in demand has given rise to a steep increase in the complexity of programs employed within industrial control systems. As a result, industries are shifting away from traditional hardware-based solutions and are placing a stronger emphasis on software to keep pace with these evolving needs.

While none of us possess a crystal ball, it seems a foregone conclusion that the automation systems of tomorrow will need to be an order of magnitude more functional, efficient, and economical. This can only mean longer programs and far greater complexity. Failure to adapt to these changes will result in becoming uncompetitive and ultimately out of business.

In light of the need for this transition, there is a growing focus on enhancing software engineering practices within industry. This emphasis is poised to become increasingly critical as companies embrace new technologies, such as digitalisation.

However, with opportunities come challenges. The adoption of any new technology often sparks uncertainty, stemming from perceived complications in integrating these innovations into existing workflows.

This means that those who implement automation systems, such as programmers and alike, will need help to learn new skills in a variety of areas. In order to make this transition smooth, they will need assistance in the process of adopting the new technologies.

Please refer to the printed magazine for the complete article

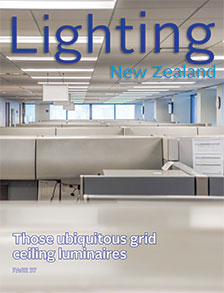

COVER STORY

Those ubiquitous grid ceiling luminaires

Walk into an office, retail store, or any commercial building with a ceiling grid, and look up. More likely than not, you are likely to see either original fluorescent troffer style lights, or the modern equivalent of an LED panel. How did they become so prevalent, do they deserve their prominent place in our lighting tool kit, and are how can we make the most of what is on offer?

For every space with a grid ceiling, there is a light fitting to fill that grid. Whether the grid is 600 mm x 600 mm or 1200 mm x 600 mm, there is a panel to suit, there are even a multitude of other sizings from small 200x300 to 600x300, or possibly now the most popular, 1200x300 format. There are also options in different shapes, from circular to fully customisable.

It is the existence of the grid ceiling that drove the popularity of this luminaire and continues to make it one of the best solutions still for any space with this ceiling type. It is so ubiquitous due to its ease of install, good light output, low cost, and ease of maintenance.

Grid ceilings have some common properties that have made them a perfect match for the LED panel. It is the ability to suspend a ceiling to a flat plane and keep that height to a constant level, generally at the 2.7 m height. This standard height makes it easy use some general rules of placement (simple spacing rules, like having a gap of two tiles and four tiles between luminaires, for example). It also allows the uniformity of the luminaires light output to be equal, with a good spread of light from a relatively high platform, but still allowing the output to easily comply with office lighting standards.

Please refer to the printed magazine for the complete article

Enlightening paths: the benefits of lighting education

Whether you are a seasoned lighting professional, an electrical contractor, or looking for a pathway to a new career, expending effort learning about lighting is never a poor investment in your time. There are so many opportunities to learn and upskill, from practical knowledge and theoretical principles to discovering the future and sifting through relevant standards and codes. There are so many sources of quality information.

The lighting industry is a diverse entity, one that stretches from those at the beginning of the chain developing knowledge and technology, those that are completing investigative research, or who design and manufacture the base componentry such as LED chips, to those that create and distribute luminaires to market.

The chain continues through to the huge network of intermediary suppliers and wholesalers who add value to product with their skills. It continues into the application side, both through engineers and lighting designers that specify luminaire selections and placement, as well as electrical contractors, selecting luminaires, upselling quality luminaires with greater benefits and installing them correctly. All these links in the chain have become successful through a lighting education, whether it be formal or on the job training, and all these links rely on each other to enhance the future of the industry.

Please refer to the printed magazine for the complete article

|